Introducing a Thorough Selection of Long Lasting Undercarriage Parts for Heavy Machinery

Introducing a Thorough Selection of Long Lasting Undercarriage Parts for Heavy Machinery

Blog Article

Make The Most Of Performance With Durable Undercarriage Components

In the realm of heavy machinery and devices, the function of undercarriage parts is paramount in making certain ideal performance and longevity. The effectiveness and effectiveness of these elements can dramatically affect the total procedure of equipment, making the choice of durable undercarriage parts a crucial decision for drivers and supervisors alike.

Advantages of Using Resilient Undercarriage Parts

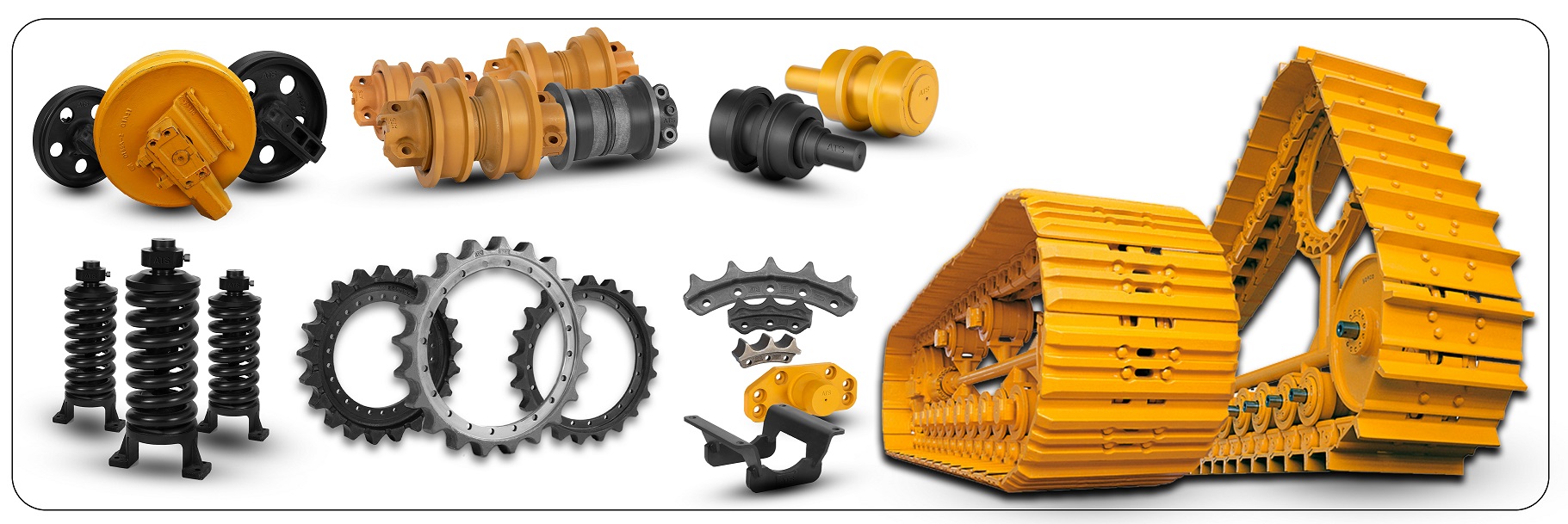

Making use of resilient undercarriage components not just enhances the longevity of heavy machinery yet also reduces maintenance expenses substantially. By purchasing high-quality undercarriage components, such as tracks, rollers, sprockets, and idlers, equipment operators can experience increased uptime and improved overall performance.

Moreover, the durability of hefty machinery is directly connected to the top quality of its undercarriage components. Durable elements can hold up against the rigors of demanding applications, making certain that the equipment continues to be operational for prolonged durations. Because of this, operators can prevent pricey downtime and upkeep costs, ultimately making the most of the roi for their equipment.

Aspects Influencing Undercarriage Sturdiness

The durability of undercarriage components in hefty equipment is affected by numerous crucial elements that directly impact performance and longevity. One of the essential aspects impacting undercarriage longevity is the quality of products made use of in production. High-quality materials, such as hardened steel, are important for standing up to the severe problems and hefty lots that undercarriage components undergo. Correct upkeep methods likewise play a vital function in determining the lifespan of undercarriage components. Normal examinations, lubrication, and prompt replacement of worn-out parts can considerably prolong the resilience of the undercarriage.

Furthermore, environmental variables can have a substantial effect on the longevity of undercarriage components. Exposure to unpleasant products, extreme temperatures, and rough working conditions can accelerate deterioration on undercarriage components. Picking undercarriage parts that are especially made to withstand these ecological difficulties is essential for guaranteeing resilience.

In addition, the design and engineering of undercarriage components have a straight impact on their resilience. Components that are made to distribute tons equally, reduce friction, and reduce anxiety focus are more probable to have a longer life-span - undercarriage parts. By considering these crucial aspects, devices drivers can make the most of the sturdiness and efficiency of their undercarriage parts

Maintenance Tips for Prolonging Undercarriage Life

Executing regular upkeep regimens is essential for extending the life-span of undercarriage elements in heavy equipment. In addition, make sure that the undercarriage is correctly lubricated according to supplier standards to decrease friction and stop premature wear.

Another essential maintenance tip is to maintain the undercarriage tidy from dirt, rocks, and particles. Accumulation in my response the undercarriage can increase wear and corrosion, resulting in costly repair services. Washing the undercarriage after procedure in severe problems is suggested to prevent these concerns.

Finally, monitoring and recording maintenance activities can assist in creating an aggressive maintenance routine. Keeping in-depth records of repair work, replacements, and inspections can give important insights right into the undercarriage's problem and performance gradually, assisting in predicting and stopping possible failures. By following these upkeep suggestions carefully, drivers can considerably boost the durability and performance of undercarriage parts in hefty equipment.

Picking the Right Undercarriage Components

Selecting appropriate undercarriage parts is critical for making the most of the efficiency and long life of heavy machinery. When it comes to choosing the appropriate undercarriage elements, there are a number of factors to take into consideration.

Furthermore, considering the top quality and online reputation of the maker is important. Choosing trusted brand names understood for producing high-performance and resilient undercarriage components can dramatically affect the general efficiency and longevity of the equipment. Furthermore, making certain that the components are suitable with the device version and correctly mounted is important for optimum performance. By carefully choosing the appropriate undercarriage elements, tools owners can improve performance, reduce downtime, and prolong the life-span of their heavy machinery.

Situation Research Studies: Enhanced Efficiency With Resilient Parts

Integrating sturdy undercarriage parts has actually demonstrated considerable improvements in machinery performance. One instance study entailed a construction business that updated its excavator's undercarriage components to a lot more durable alternatives.

In an additional circumstances, a mining procedure replaced the undercarriage components of its excavator with top notch, resilient options. This switch caused an amazing renovation in the bulldozer's maneuverability and general performance. The device can browse challenging surfaces extra efficiently, causing boosted operational efficiency and decreased gas intake.

In addition, a logging business purchased sturdy undercarriage parts for its forestry equipment. The upgraded elements displayed extended life-span and enhanced resistance to abrasion from rough terrain. The business experienced decreased maintenance expenses and enhanced equipment uptime, ultimately increasing its bottom line. These study highlight the concrete benefits of using durable undercarriage parts in maximizing equipment efficiency and durability.

Verdict

Finally, using long lasting undercarriage parts can considerably improve performance and long life of hefty machinery. Aspects such as proper maintenance and choosing the right parts play a crucial role in optimizing undercarriage toughness. By carrying out these techniques, businesses can lower downtime, my latest blog post boost efficiency, and eventually save see this page on functional expenses. Case research studies have revealed that buying sturdy undercarriage parts can bring about boosted general performance and efficiency in numerous markets.

The efficiency and efficiency of these components can substantially influence the overall operation of equipment, making the option of durable undercarriage components a critical decision for drivers and managers alike.Incorporating long lasting undercarriage components has actually demonstrated considerable improvements in equipment efficiency. These case studies highlight the substantial advantages of making use of durable undercarriage components in maximizing equipment performance and longevity.

In conclusion, making use of sturdy undercarriage parts can considerably boost performance and longevity of heavy machinery (undercarriage parts). Case studies have shown that investing in durable undercarriage parts can lead to improved general efficiency and performance in numerous sectors

Report this page